Garbage and Linen chutes

TECHNICAL AND MATERIAL DETAILS

Refuse and linen chute systems can be used in apartment buildings, hotels, commercial buildings and hospitals. Kivolt provides refuse and linen chutes that have been designed and manufactured after years of experience and engineering. We produce chutes from the following high quality materials:

- Stainless Steel: Kivolt strongly recommends the use of stainless steel for the manufacture of refuse chutes. Stainless is highly resistant to the humidity, acid and alkalis contained within refuse.

- Galvanized Steel: It does not have the same protective characteristics of stainless steel, yet, it is used extensively for refuse chutes.

Linen chutes are the most efficient method of quickly and economically disposing of dirty linen in multi storey buildings.

The dirty linen is usually bagged before loading into the chute. Side hung doors with large openings are therefore the normal standard on linen chutes. Increasing cost of using lifts and maintaining labour in hotels and hospitals reinforces the decision to install a chute.

Standards:

- 1703: 1977

- BS 5906: 2005

- VDI 2162

Thicknesses and Guages:

Kivolt provides the following material gauges:

- 1.5mm (16 Gauge)

- 2.0mm (14 Gauge)

- 3.0mm (11 Gauge) (when specified)

Vent Tube, Insect Screen and Exhaust Fan

Essential for keeping insects out of the system and maintaining a healthy air flow.

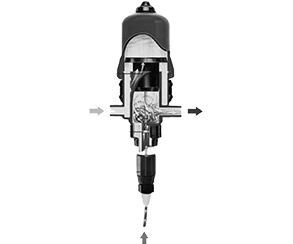

Solenoid Valve

Electrically operated valve controlling the flow of water to the sanitizing unit..

Disinfecting and Sanitizing Unit

Part of the automatic cleaning system of the chute. The sanitizing unit mixes soap along with the water where by the interior surfaces are sprinkled with water from alternate floors by sprinklers of ½” capacity.

Access Door

Access door is located below the vent tube on the last floor. It is used for accessing the equipment in case of maintenance or revision of the chute. When opening the access door, the equipment located inside consists of the motor unit, solenoid valve, brush, disinfecting and sanitizing unit.

Cleaning System and Brushing Device

Chute cleaning system specifically designed to clean the total vertical length of the internal surface of all chutes. Where by, it includes the brush unit and motor unit.

Control Panel

Controls the entire automated systems within the chute. Operates the cleaning system. Controls the function of electromagnetic door locks with the presence of an emergency button which isolates electricity and stop all the running functions.

Intake Throat

On each floor there is an intake throat for the hopper door.

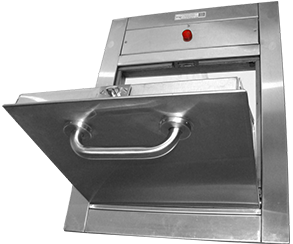

Hopper Door

Hopper doors are provided in the service room on each floor and are designed to eject loose or bagged refuse (discharge garbage) directly into a refuse chute or a container. Hopper doors have an effective self-sealing system.

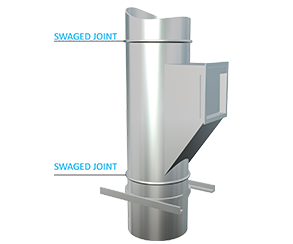

Clamp Ring and Supporting Frame

Cut, shaped and drilled from 35x35x3 mm or (other sizes are applicable for use) Mild steel angle with a rigid, welded construction. The frame holds a metal clamp band. It is rust proof for internal use and hot dip galvanized for external use.

Swaged Joint

Used to join certain sections of duct.

Sound Damping

Metal refuse chutes can produce, uncomfortable levels of noise. A factory applied coating of a proven sound damping compound will dramatically reduce noise level produced by resonant vibrations in metal refuse chutes. Factory applied at the same thickness as the metal substrate or more and over the total area of the exterior surface of the refuse chute, (except refuse, hopper face and side hinged door faces).

Automatic Fire Sprinklers

Cleaning Sprinklers:

Spray head located on all floors behind the door opening for cleaning issues.

Fire Sprinklers:

Glass bulb sprinklers installed for fire detection inside the chute on each floor 1/2” IPS, 68°C (165°F).

Glass Sprinklers can be used in conjunction with a normal water supply at a pressure of up to 8 bar.

Smoke Detection System:

This system shall be provided by the fire alarm subcontractor.

Fire Cut-Off Door

Fire Cut Off Door has a horizontal rolling door held by a spring on each side connected to a fusible link. In case of excessive heat (or fire) the link gets fused at 165° F (68°C) causing the door to roll shut. The discharge is 1.5 hours fire rated.

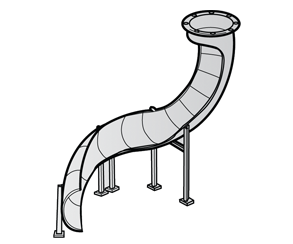

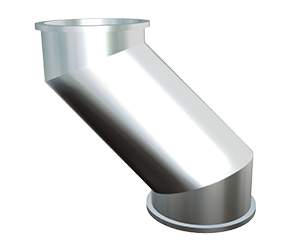

Elbow

Factory fabricated from the same material as the refuse chute, but in a heavier gauge to withstand the impact of falling bags. Offsets should not be less than 45° from the horizontal. Offsets are fabricated to all diameters of refuse and linen chutes provided by Kivolt.

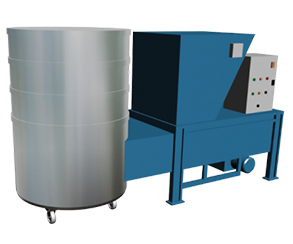

Garbage Compactor

Garbage Container

Tipping Truck Container Skip

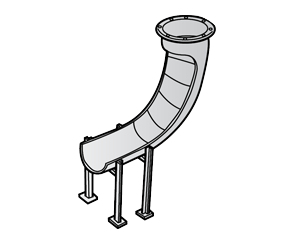

Straight Short Deceleration Track

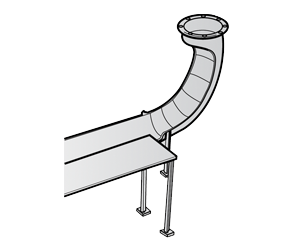

Deceleration Track Delivering Bagged Linen to Sorting Table