Cable Management Support System

TECHNICAL AND MATERIAL DETAILS

Our systems provide an economical solution for electrical, mechanical and industrial supports. They can be used for a wide variety of applications in the construction industry. Our channels and accessories are well designed to provide necessary support for cable trays, cable ladders, and cable trunking. Our cable management support system is manufactured according to common standards from high quality raw materials.

Standards:

- IEC 61537:2007

- BS EN 61537:2007

- NEMA VE 1 – 2009

- NEMA VE 2 – 2006

- NEC (ANSI / NFPA 70)

Applications:

- Metal Framing / Electrical

- pplications

Pipe & Conduit Supports - Tunnel Pipe Stanchions

- Beam Attachments

- Pipe Risers

Finishes:

- Pre-Galvanized finish (ASTM A653M coating G90 and G60).

- Hot Dip Galvanized after fabrication (ASTM A123 or BSEN ISO1461:2009).

- Other custom coatings are available upon request.

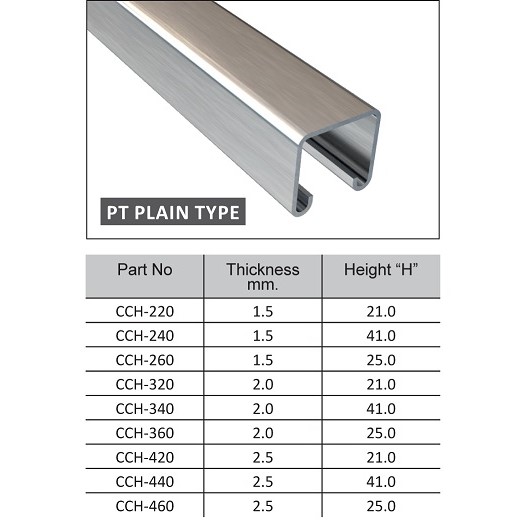

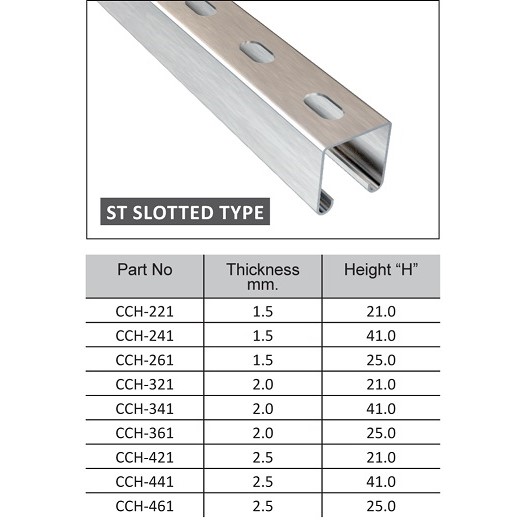

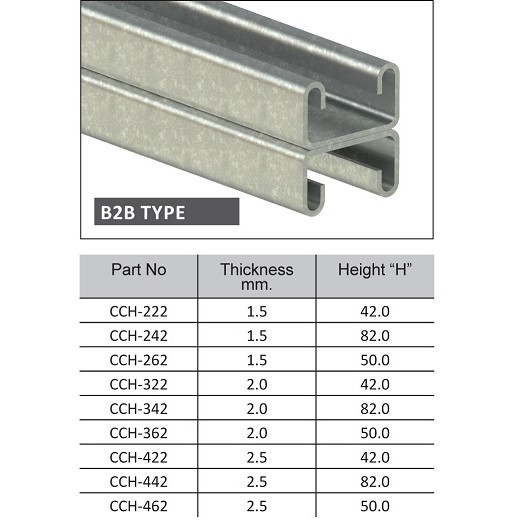

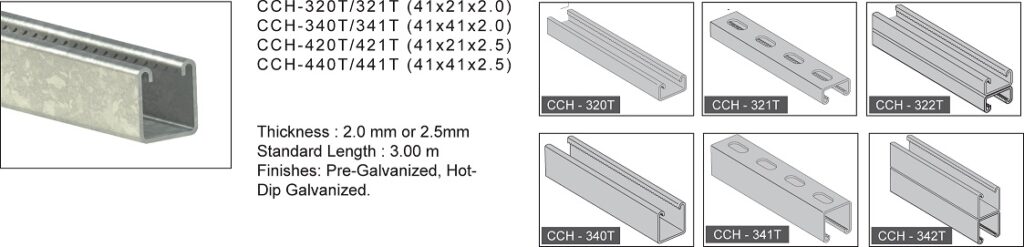

C-Channel Types

Plain Type C-Channel

Slotted Type C-Channel

Back to Back Type C-Channel

Materials

Kivolt’s metal framing channels are manufactured from:

- Hot rolled steel S235JR as per EN 10025 / ASTM A-1011 CS Type B (formerly ASTM A569 or ASTM A570)

- Cold rolled steel DC01 as per EN 10130 / ASTM A1008 CS Type B (formerly ASTM A-366) and then: Hot- dip galvanized as per BS EN 1461 (formerly BS 729) / ASTM A123 or Electro plated as per EN 12329 / ASTM B633 (Electrodeposited coatings of zinc on iron and steel)

- Pre-galvanized steel DX51 D+Z as per EN 10346 (G180 and G275 is available upon special request) which supersedes EN 10327 which is a replacement of EN 10142 which in turn supersedes BS 2989 / ASTM A653M zinc coated (hot-dip galvanized) iron and steel CS (commercial) or SS (structural) quality G60 and G90 is available upon special request (formerly ASTM A527M) / ASTM A924 (coating) (formerly A525)

- Stainless steel 1.4301 as per EN 10088-2 (formerly BS 1449 Part 2 / ASTM A240M, Grade AISI 304)

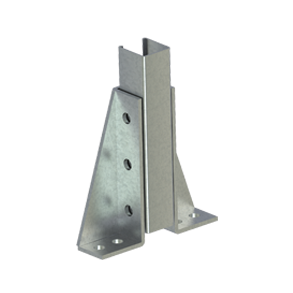

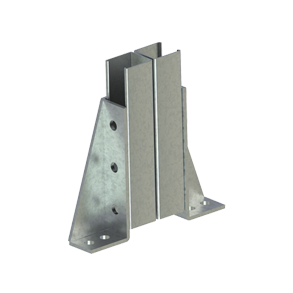

Cantilever Arm Brackets

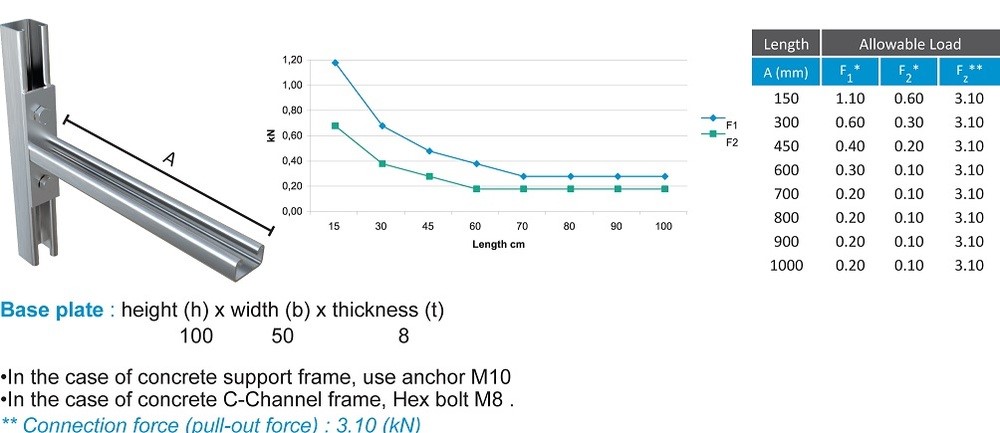

C-Channel 41 x 21 x 2.5 mm

Base Plate: 100 x 50 x 8 mm

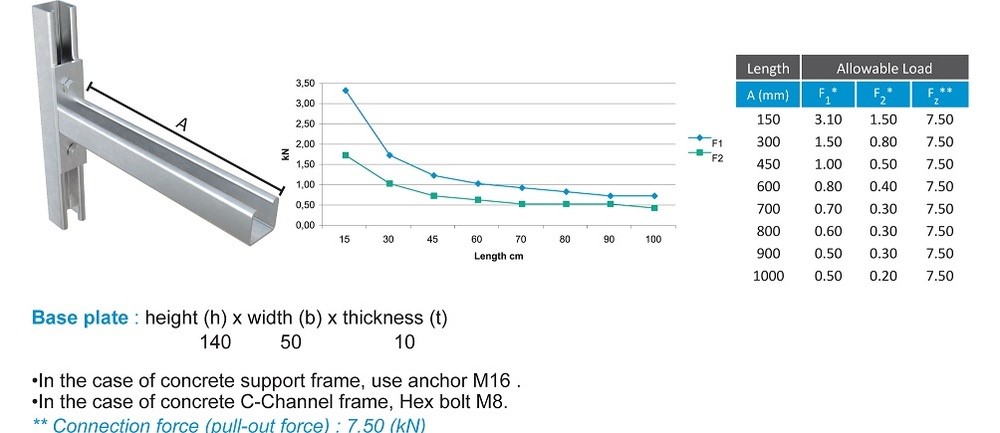

C-Channel 41 x 21 x 2.5 mm

Base Plate: 140 x 50 x 10 mm

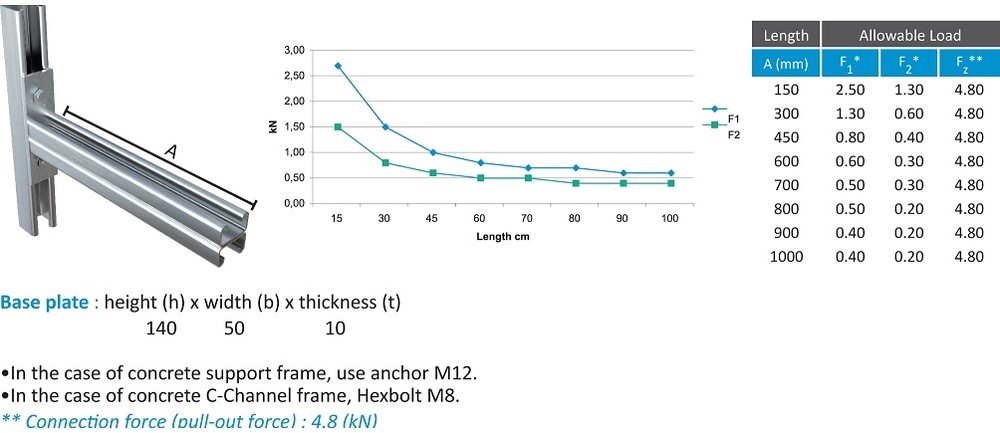

C-Channel 41 x 21 x 2.5 mm (Back to Back)

Base Plate: 140 x 50 x 10 mm

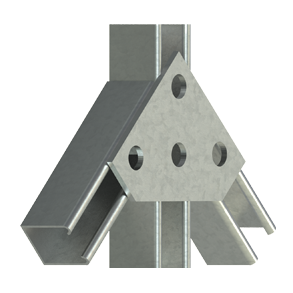

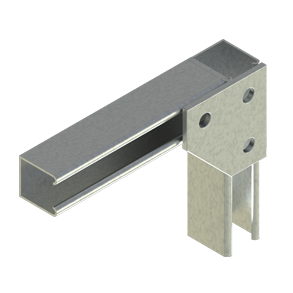

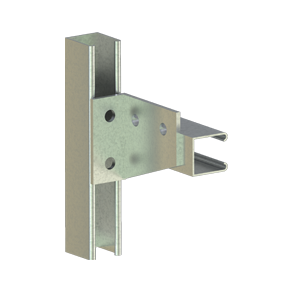

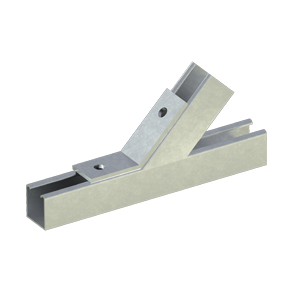

Fittings

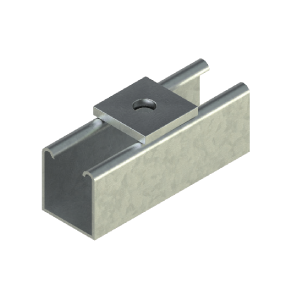

Square Washer

Splice Plat

Square Splice Plat

Angle Plat

L-Plat

T-Plat

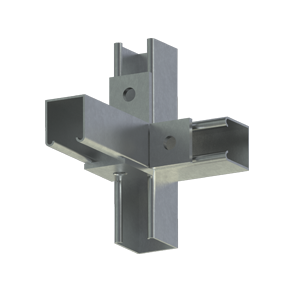

Plus Plat

45 Plat

90 Plat

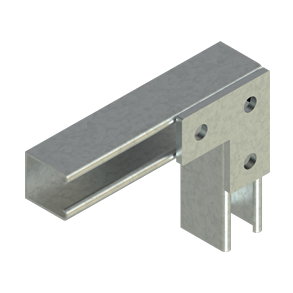

L-Bracket

Angle Plat

Angular Bracket

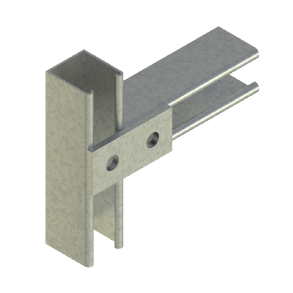

T Corner Left

T Corner Right

T Corner Center

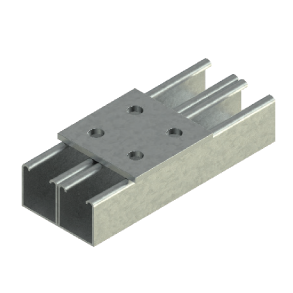

Double Wing Joint

Single Channel Gusseted Bracket

Double Channel Gusseted Bracket

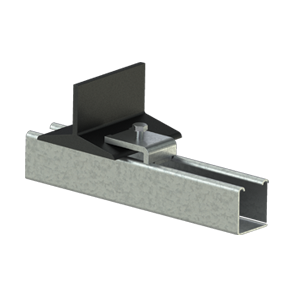

Beam Clamp